A CAN bus termination resistor is a critical component in ensuring stable communication between automotive systems. It helps in reducing signal reflections, preventing data corruption, and maintaining the integrity of the CAN bus network. For industries in Houston, using proper termination resistors is essential to optimize automotive communication and avoid system failures, particularly in complex vehicular networks. In this guide, we will explain everything you need to know about CAN bus termination resistors and their application in Houston.

Introduction

The “CAN Bus Termination Resistor Houston” is an integral part of modern automotive communication systems, ensuring reliable data transmission across various systems. In Houston, where automotive and industrial applications rely heavily on stable communication, the proper implementation of CAN bus termination resistors becomes even more essential. This article aims to explore the technicalities and the importance of these resistors while providing insights into how they work, their installation process, and their use in the Houston market.

What is a CAN Bus Termination Resistor?

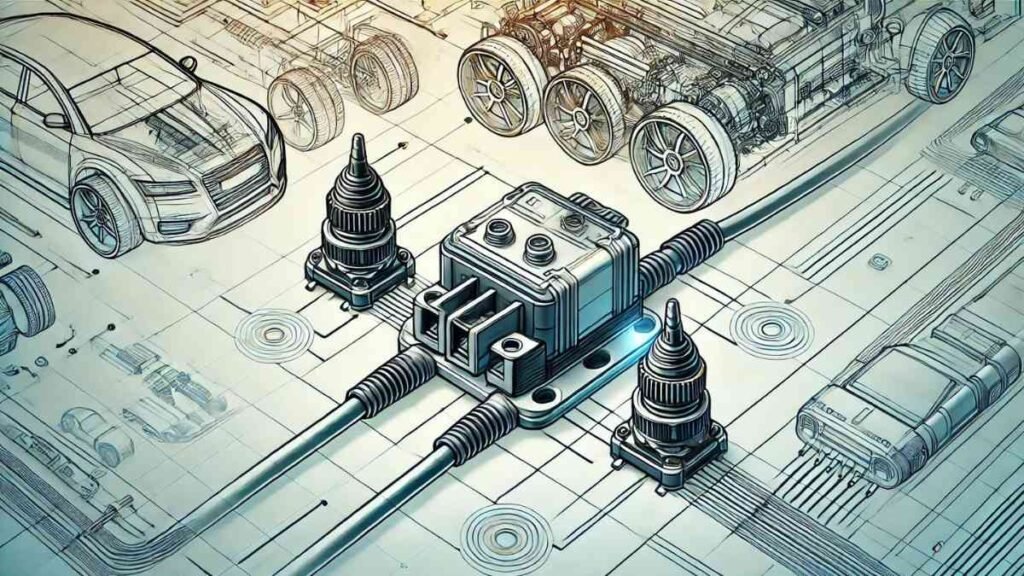

The CAN bus (Controller Area Network) is a communication network used in vehicles and industrial systems for real-time data exchange. A CAN bus termination resistor is a device used to prevent signal reflections on the CAN bus lines. These resistors, typically valued at 120 ohms, are placed at both ends of the CAN bus to ensure the integrity of the signal transmission.

Importance of CAN Bus Termination Resistors

Signal integrity in a CAN bus network is crucial to prevent data errors and ensure seamless communication between the different modules. When a CAN bus is not properly terminated, signal reflections can occur, leading to data corruption, communication errors, and even complete network failure. For automotive applications in Houston, these issues can result in costly repairs and system malfunctions, making the proper installation of “CAN Bus Termination Resistor Houston” an important task.

Applications of CAN Bus Termination Resistors in Houston

- Automotive Industry

Houston, known for its large automotive and industrial sector, relies heavily on CAN bus systems to control and monitor vehicle functions like engine control, braking, and safety systems. A properly terminated CAN bus ensures reliable data transmission between various vehicle modules, reducing the risk of errors or malfunctions. - Industrial Automation

In the industrial automation sector, the CAN bus is widely used for controlling machinery and equipment. Termination resistors ensure that machines communicate efficiently, reducing the chances of system failures and production halts. The “CAN Bus Termination Resistor Houston” market is integral to keeping these industries operating efficiently.

How to Install a CAN Bus Termination Resistor

Proper installation of a “CAN Bus Termination Resistor Houston” is essential for optimal performance. Here’s a step-by-step guide to ensure that you install the resistor correctly:

- Identify the Bus Ends

First, determine the two physical ends of your CAN bus network. The termination resistors should only be placed at these two points to ensure signal integrity. - Select the Correct Resistor

A standard 120-ohm resistor is typically used for CAN bus termination. Ensure that the resistor is placed between the CAN-H (high) and CAN-L (low) lines. - Test the Network

Once the resistors are installed, test the network using an oscilloscope or CAN bus analyzer to ensure that signal reflections are minimized, and data transmission is smooth.

Common Issues with CAN Bus Termination Resistors

- Incorrect Placement

One common issue is the incorrect placement of termination resistors. Installing them in the wrong locations can cause data transmission problems and system errors. - Wrong Resistor Value

Using a resistor that is not rated for 120 ohms can lead to significant signal distortion and communication errors in the CAN bus. - Faulty Resistors

Over time, resistors can degrade due to heat or electrical stress. Faulty resistors can lead to intermittent communication problems or complete network failure.

Benefits of Proper CAN Bus Termination

- Improved Signal Quality

Proper termination significantly improves the quality of signals within the CAN bus network, reducing the risk of data errors and communication failures. - Extended Network Life

By minimizing signal reflections and maintaining a stable communication system, proper termination helps extend the life of the network and prevents wear and tear on system components. - Reduced Downtime

In industries where downtime can be costly, ensuring that CAN bus systems are correctly terminated helps reduce the risk of communication failures, leading to more efficient operations.

Why CAN Bus Termination is Crucial for Houston

Houston’s thriving automotive and industrial sectors require robust communication networks. “CAN Bus Termination Resistor Houston” plays an essential role in ensuring these networks function optimally. Given the high demand for reliable and uninterrupted communication in these industries, using quality termination resistors in Houston’s CAN bus systems can make the difference between seamless operations and costly disruptions.

Conclusion

The importance of a “CAN Bus Termination Resistor Houston” cannot be overstated in automotive and industrial applications, particularly in Houston, where industries rely heavily on seamless communication between various systems. By understanding the role, installation process, and importance of these resistors, businesses and automotive professionals can ensure that their CAN bus networks operate at peak efficiency. Proper termination not only improves signal quality but also extends the longevity of the system, preventing costly breakdowns and ensuring smooth operations.

For More Visit, MirrorMagazine.co.uk